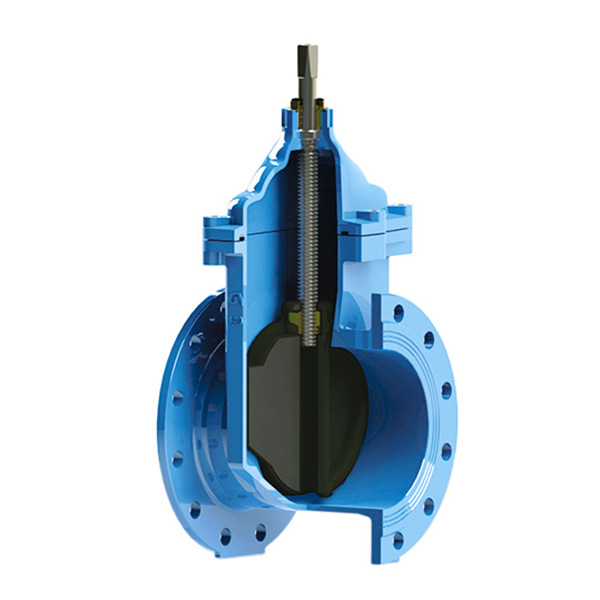

Soft seal ( resilient seat) gate valve

ANSI standard soft seal ( resilient seat) gate valve

DIN soft seal ( resilient seat) gate valve F4/F5

BS standard soft seal ( resilient seat) gate valve

SABS standard soft seal (resilient seat) gate valve

1.OEM is available

2.Full set of valve moulds with different weight to satisfy with customer’s different requirement.

3.Precision casting and sand casting

4.Our own foundry to guarantee fast delivery and quality

5.Epoxy coating with WRAS approved

6.The price of gate valve with big size is very advantageous

7.Gate valve with extend stem is available

8.Certificates available: WRAS/ DWVM/ WARC/ ISO/CE/NSF /KS/TS/BV/SGS/ TUV …

9.Professional QC department to control product quality, and each valve will be arranged hydro test twice before shipment

10.Mill test certificate and inspection report will be provided for each shipment

1.The quality of rubber is related to the sealing performance of the valve. The rubber used in our factory is a European high-tech rubber formula, which can overcome the defects of poor sealing, elastic fatigue, rubber aging, rust and water leakage of ordinary valves, thereby prolonging the service life of the valve.

2.Valve compact structure, reasonable design, small operation torque, easy opening and closing.

3.The inside and outside of the valve body is coated with powder epoxy resin, which has a beautiful appearance and is not easy to rust and corrode.

4.Widely used in tap water, sewage, building water supply and drainage, factory cooling water, air conditioning water system, hydraulic engineering, fire water, etc.