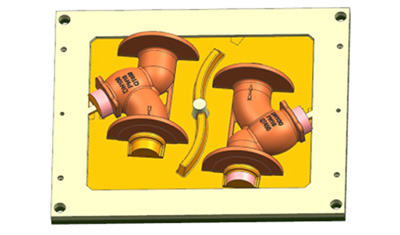

Casting

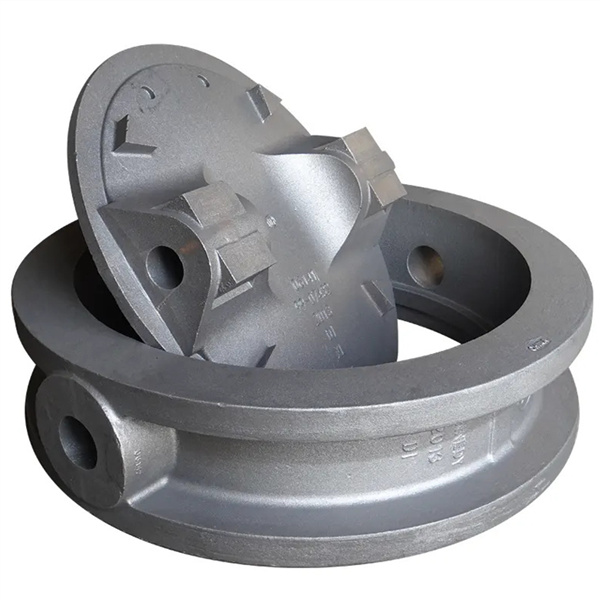

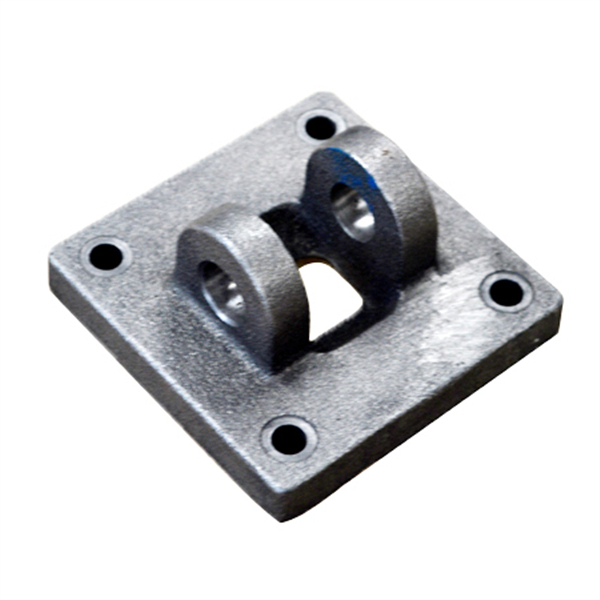

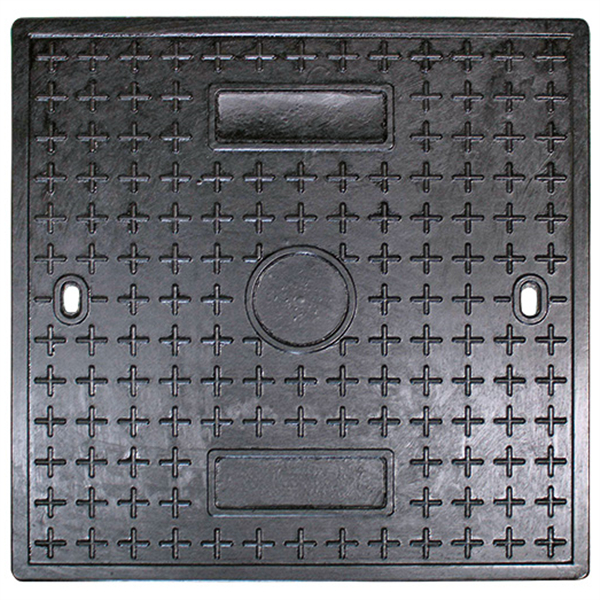

Valve body/Pump body/Machinery parts/Farm machinery parts/Auto parts/Medical equipment parts/Food machinery parts/Manhole cover/Grates

1.Sand casting for Grey cast iron,Ductile iron and Cast steel :

Min. Unit Weight:0.1 kg- Max. Unit Weight:300kg

2.Precision casting for Stainless steel CF8 and CF8M:

Min. Unit Weight:0.02 kg- Max. Unit Weight:30kg

1.OEM and ODM is available

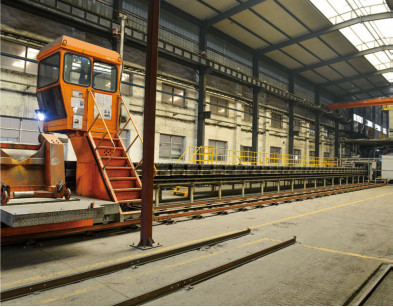

2.3 automatic casting lines for sand casting to cover different sizes of castings

3.CNC machining center to make and repair mould

4.4 sets of special equipment for heat treatment

5.Complete quality control center and inspection facilities

6.Each lot of castings are of Traceability

7.2 lines of Epoxy coating, powder with WRAS /NSF approved

8.Guarantee on-time Delivery time

9.Mill test certificate and inspection report will be provided for each shipment

SINTO Horizontal Parting Molding Line FBOIII

SINTO Horizontal Parting Molding Line FDNX

SINTO Horizontal Parting Molding Line FBOIII

Z148 Circular molding Line

FM Molding Line

Core-making Shop

Post Treatment Shop

Machining workshop

Pattern design & manufacturing capability

Machining tooling design & manufacturing capability

Inspection facilities for castings: spectrometer,carbon sulfur analyzer,metallurgical microscope,tensile strength testing equipment,pressure testing equipment,adhesive force testing equipment,CMM,hardness tester,etc. From incoming inspection to finished product,quality is checked and monitored in the whole process.

Inspection devices for casting sepoxy coating: impact tester, thickness tester, spark detector,Salt spray testing machine, adhesiveness tester.