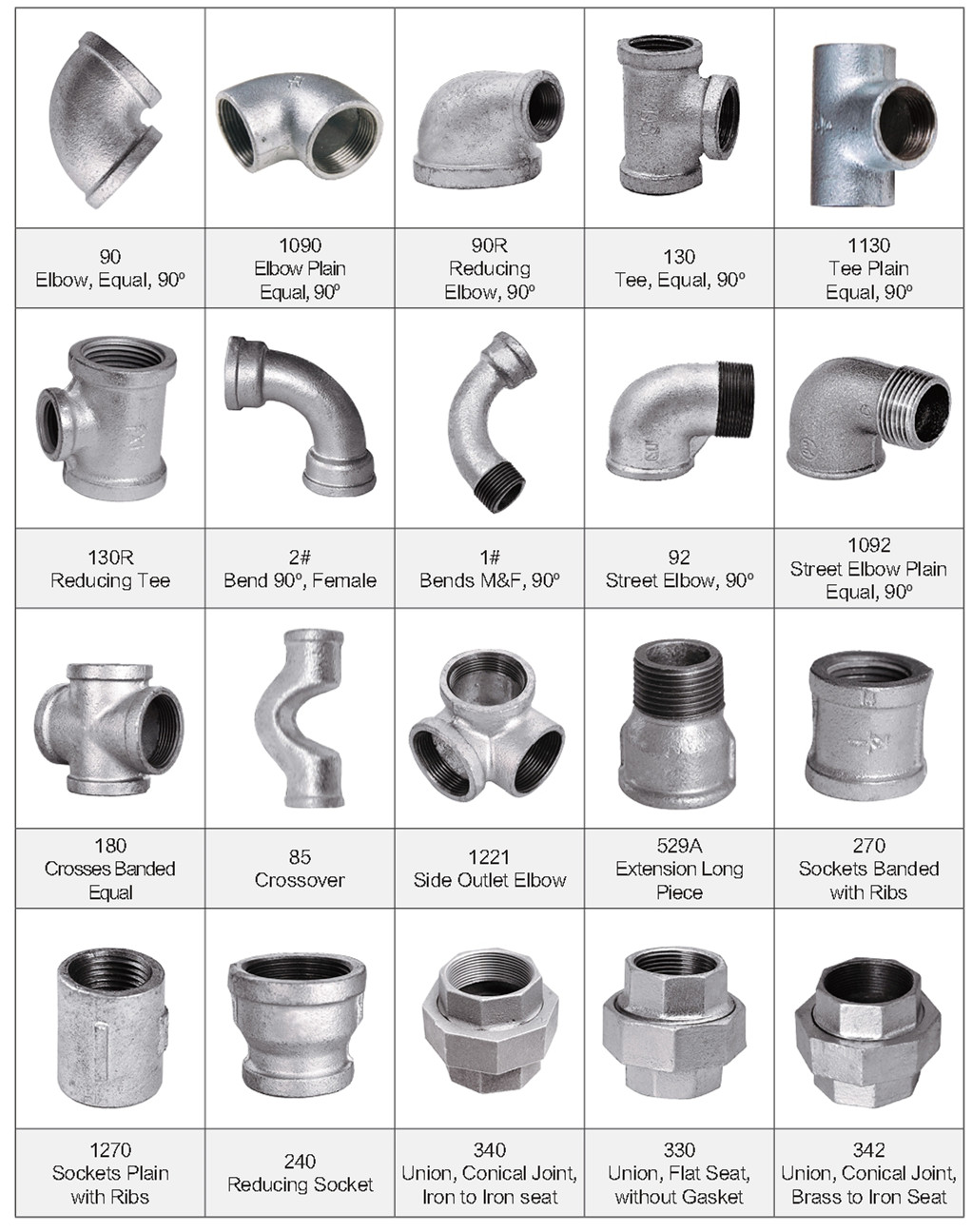

Water supply malleable iron pipe fitting

Our malleable iron pipe fittings can be used in a wide variety of applications involving steam,air,water,gas,oil and other fluids.Suitable for fire piping system,home decoration, equipment and so on.In general,malleable iron is very good for applications requiring good tensile strength and the ability to flex without breaking(ductility).The following types of malleable iron–black and galvanized pipe fittings can be supplied:

Malleable iron is produced by a casting method just like cast iron,but they are actually quite different from each other. Although Malleable iron fittings start out as cast iron fittings, they are then transformed into a much more durable malleable iron through a heating process.

Malleable iron pipe fittings are those fittings having the property of malleability.This is a physical property of metals and metalloids,or any kind of matter. We call a metal malleable when it can easily be deformed,especially by hammering or rolling,without cracking the metal. Malleability is important to form pressing materials such as metals and plastics.

The manufacturing process of Malleable iron pipe fittings:

Malleable iron fittings are made using the most sophisticated metallurgical and processing controls. These fittings are usually made through casting and an automatic precision pattern extrusion. Malleability occurs due to metallic bonding present in most metals. The varieties of free electrons formed during the loss of electrons emerging from the outer-most electron shells of the metal atoms lead to layers of the metal sliding over one another. This process makes the metal malleable.