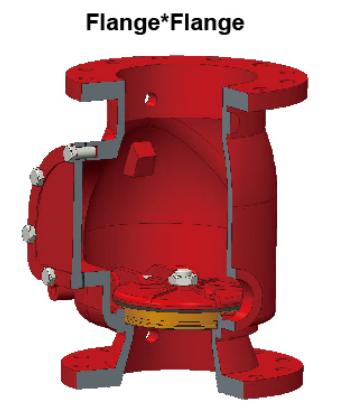

Wet alarm check valve UL/FM Approved

Features: Installation height of the valve according to customer’s requirement; The valves could be installed indoor or outdoor through wall as to customer’s requirement; Electrostatic Spraying both inside and outside of the body.

The wet alarm valve is designed for applications where the water is unlikely to freeze. The water staying pressurized in the pipes is released over the fire area after the sprinkler is activated due to fire. The pressurized water system is not only feed continuously, but also fills in the retard chamber. After the chamber is filled, the pressure switch on the chamber is actuated. The pressure switch sends the alarm information to the fire warning system or the automation system. After the pressure switch is actuated, the water is delivered to the water-motor gong and releases a mechanical alarm.They are used in wet line of sprinkler system,fire protection system

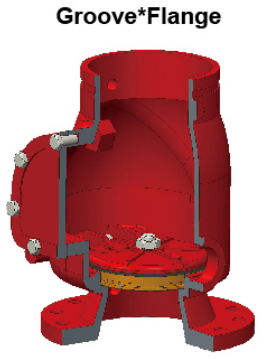

Size:121mm*58mm*112mm

Pipeline entrance:Φ22.5mm

Working temperature:-40℃-60℃

Pressure connection Nylon 1/2NPT(R21/2)thread

Factory setting:5-7PSI

Max working pressure:250PSI

Environment specifications The dust proof and water proof level is IP66

Differential pressure: Generally 1 PSI

Certificates available: UL/FM

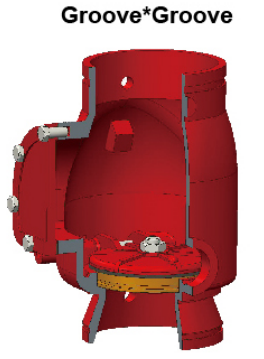

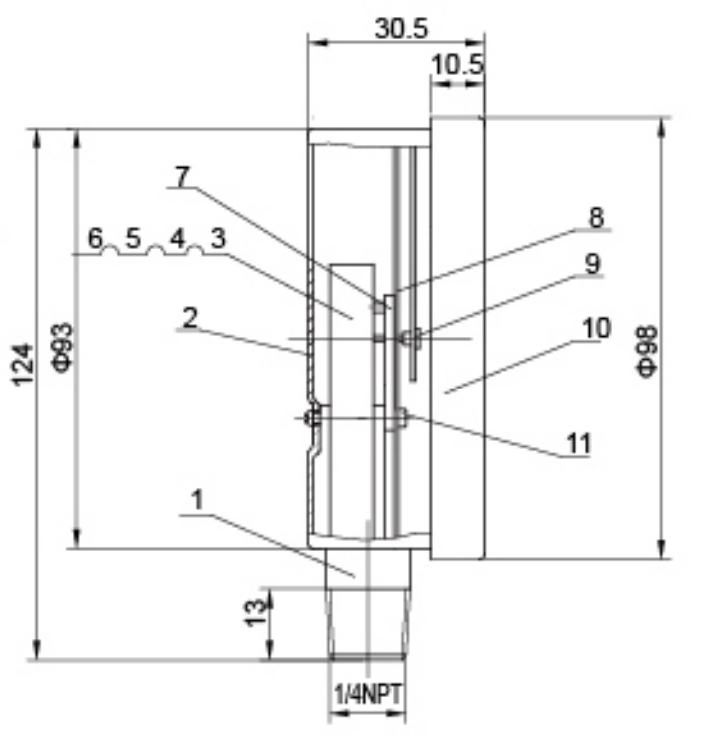

Size:1/4” NPT

Pressure:0-300PSI/0-600PSI

Working temperature:0℃-80℃

Design standard: UL393/FM2311

Test standard:UL393/FM2311

Certificates available: UL/FM

|

No. |

Name |

Qty |

Material Science |

Remark |

|

1 |

Base | 1 | HPb59-1 | GB/T 2040 2008 |

|

2 |

Watchcase | 1 | 1008 | SAE J1392 2008 |

|

3 |

Spring pipe | 1 | Qsn0.8-2 | GB/T 5231-2012 |

|

4 |

Rivet | 2 | HPb59-1 | GB/T 2040-2008 |

|

5 |

Connecting rod | 1 | H62 | GB/T 2040-2008 |

|

6 |

Free end | 1 | H62 | GB/T 2040-2008 |

|

7 |

Inner core combination | 1 | HPb59-1 | GB/T 2040-2008 |

|

8 |

Dial plate | 1 | HPb59-1 | GB/T 2040-2008 |

|

9 |

Pointer component | 1 | Al | GB/T 3880-2006 |

|

10 |

Watchcase | 1 | PC | GB/T 35513.1-2017 |

|

11 |

Rivet column | 2 | HPb59-1 | GB/T 2040-2008 |

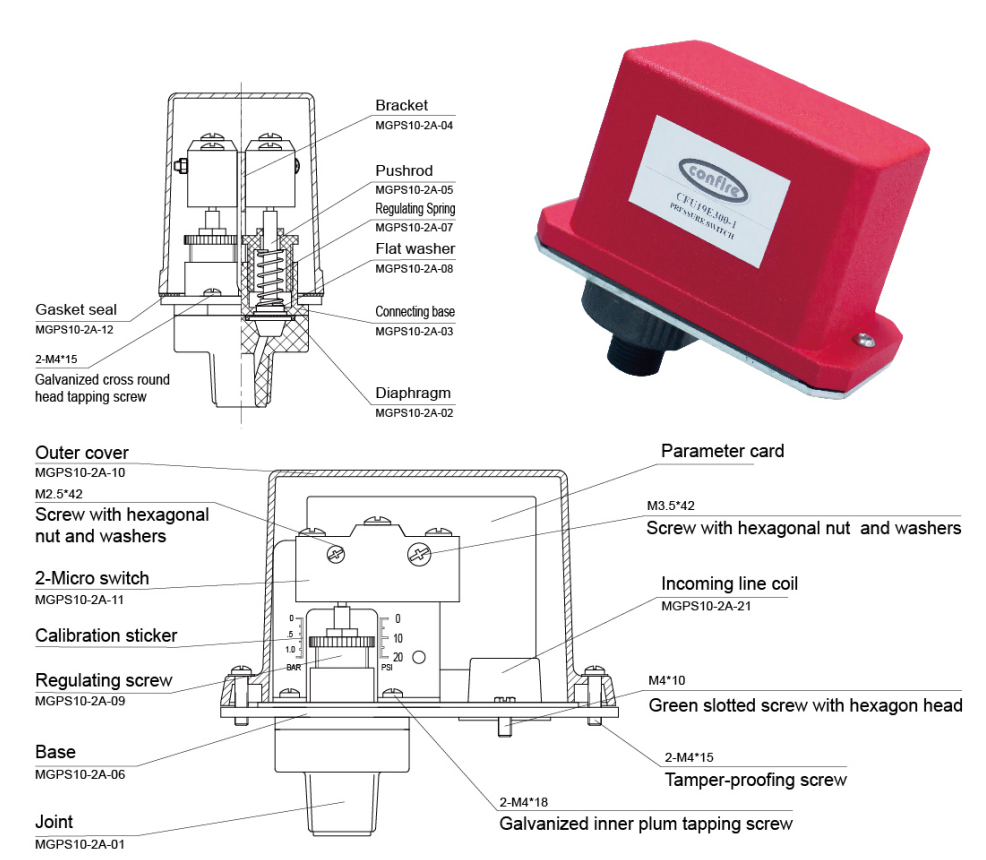

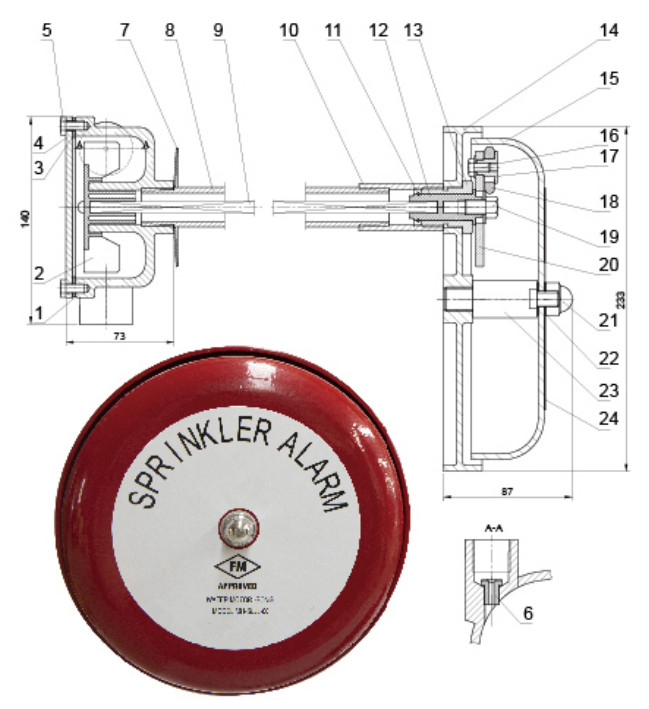

Pressure:0-300PSI

Working temperature:0℃-100℃

Design standard: FM1055

Test standard:FM1055

Certificates available: UL/FM

|

No. |

Name |

Figure Number |

Qty |

Material |

|

1 |

Driver shell |

MH-SLJL -01 |

1 |

ALUMINIUM ALLOY |

|

2 |

Impeller |

MH-SLJL -02 |

1 |

DELRIN |

|

3 |

Sealing gasket |

MH-SLJL -03 |

1 |

EPDM |

|

4 |

Cover |

MH-SLJL -04 |

1 |

1045 OR SS304 |

|

5 |

Bolt |

|

6 |

1045 OR SS304 |

|

6 |

Nozzle |

MH-SLJL -05 |

1 |

C954 |

|

7 |

Gasket |

MH-SLJL -06 |

1 |

1566 |

|

8 |

Support pipe |

MH-SLJL -07 |

1 |

1045 OR SS304 |

|

9 |

Drive shaft |

MH-SLJL -08 |

1 |

ALUMINIUM ALL OY |

|

10 |

Sleeve |

MH-SLJL -09 |

1 |

1045 OR SS304 |

|

11 |

Internal circlips |

MH-SLJL -10 |

1 |

SS304 |

|

12 |

Drive shaft adaptor |

MH-SLJL -11 |

1 |

DELRIN |

|

13 |

Supporting screw |

MH-SLJL -12 |

1 |

ALUMINIUM ALLOY OR SS304 |

|

14 |

Bell seat |

MH-SLJL -13 |

1 |

ALUMINIUM ALLOY |

|

15 |

Gong |

MH-SLJL -14 |

1 |

ALUMINIUM ALLOY |

|

16 |

Bolt |

|

1 |

ALUMINIUM ALLOY OR 1045 |

|

17 |

Support nut |

MH-SLJL-15 |

1 |

ALUMINIUM ALLOY |

|

18 |

Striker |

MH-SLJL-16 |

1 |

PHENOLIC RESIN |

|

19 |

Bolt |

MH-SLJL-17 |

1 |

ALUMINIUM ALLOY OR SS304 |

|

20 |

Joint |

MH-SLJL-18 |

1 |

ALUMINIUM ALLOY |

|

21 |

Screw nut |

MH-SLJL-19 |

1 |

ALUMINIUM ALLOY OR SS304 |

|

22 |

Gasket |

MH-SLJL-20 |

2 |

DELRIN |

|

23 |

Supporting post |

MH-SLJL-21 |

1 |

ALUMINIUM ALLOY OR SS304 |

|

24 |

Tag |

MH-SLJL-22 |

1 |

PAPER |

1.Long service life with resilient seat cycling test at least 5000 times

2.Full size range can satisfy with customer’s different requirement

3.Our own foundry to guarantee fast delivery and quality

4.Multiple O-ring sealing structure to protect the stem under pressure during operation and maintenance, it causes no damage to the operator.