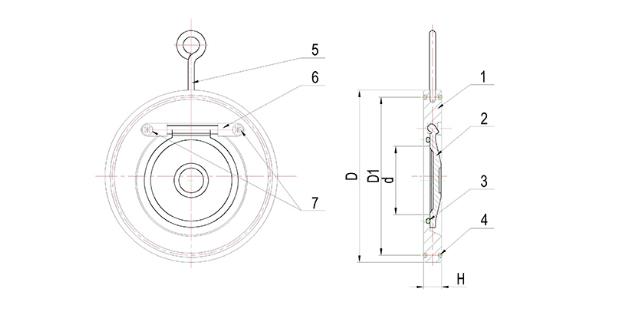

Sandwich type single disc swing check valve

| Item | Part | Material | Qty | ||

| 1 | Body | A216-WCB | A351-CF8 | A351-CF8M | 1 |

| 2 | Disc | A216-WCB | A351-CF8 | A351-CF8M | 1 |

| 3 | O-ring | Viton | Viton | Viton | 1 |

| 4 | Extemal O-ring | Viton | Viton | Viton | 2 |

| 5 | Hook | 304 | 304 | 304 | 1 |

| 6 | Stem stopper | 304 | 304 | 316 | 2 |

| 7 | Axis screw | 304 | 304 | 316 | 2 |

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and inspection report will be provided for each shipment

4.Rich operating experience for project orders

Sandwich type single disc swing check valve use a swinging disc to allow or block flow. Their design allows them to be fitted in extremely tight spaces – where the flanged check valve can not be used. The wafer check valves have molded bodies around the area where the disc opens up. This is the most important difference between the above two types of valve.

While at first glance this may just seem like a space issue, the presence of a valve body as opposed to the bare bones wafer check actually makes a big difference in the functionality of the valve. Because flanged check valves are flanged in place, there isn't much room for the disc to open in the pipe line. That means flow is often restricted within the check valve.

Do not need any maintenance,easy to make spare part replacements.

No need for additional gaskets for installation on the pipeline.

With its long neck design, suitable for insulation application.

Spring feature on disc can be added on request.