KD Mechanical Diaphragm Metering Pump

Supply Voltage

Single Phase: 110V- 240V

Three Phase: 220V- 440V

Frequency: 50Hz or 60 Hz

-

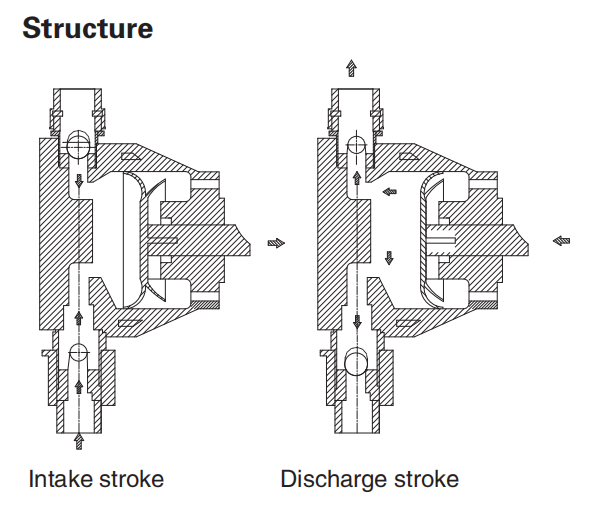

Working Principle

Diaphragm, metering Max. Permissible Fluid Temperature

60℃ Casting Parts Material

PVC, PTFE, SS304, SS316 Maximum Stroke Rate

150SPM ( 50Hz ) / 180SPM ( 60Hz ) Maximum Drive Rating

60W Maximum Caliber

Rc 1/2" or 10×16mm Maximum Discharge-side Pressure

1.0MPa ( 10bar ) Flow Rate Range

14 -130L/h ( 50Hz ) / 17-156L/h ( 60Hz ) Maximum Viscosity

500mm²/s Main Applications

Chemical, flocculant, water treatment, etc. Model

50Hz

60Hz

Pressure

Motor Power ( w )

Size and Connection

Flow ( LPH )

Flow

( GPH )SPM

Flow ( LPH )

Flow

( GPH )SPM

Bar

Psi

PVC

PTFE

SS304/SS316

JBB 15/1.0

14

3.7

100

17

4.4

120

10.0

145

60

6×10

PE hose socketedRc 1/2" Internal thread

6×12

Pipe union weldingJBB 25/1.0

25

6.6

100

30

7.9

120

10.0

145

JBB 40/0.7

38

10

150

46

12

180

7.0

102

JBB 60/0.6

60

16

100

72

19

120

6.0

87

10×14

PE hose socketed6×16

Pipe union weldingJBB 80/0.5

80

21

100

96

25

120

5.0

73

JBB 100/0.4

100

26

150

120

32

180

4.0

58

JBB 130/0.4

130

34

150

156

41

180

4.0

58

Remark

Parameter table above is only a part of whole. For more, please contact us directly.