Grooved coupling UL/FM Approved

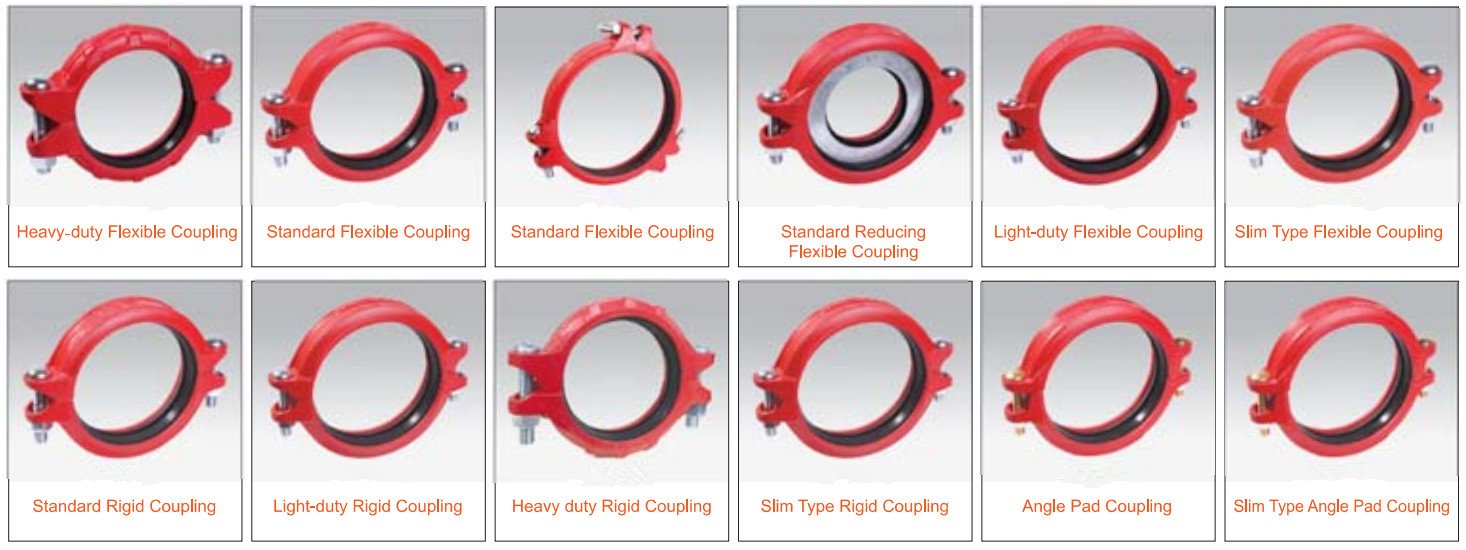

Heavy-duty/standard/light-duty flexible coupling, standard reducing flexible coupling, slim type flexible coupling;

Standard/light-duty/Heavy-duty rigid coupling, slim type rigid coupling;

Angle pad coupling, slim type angle pad coupling;

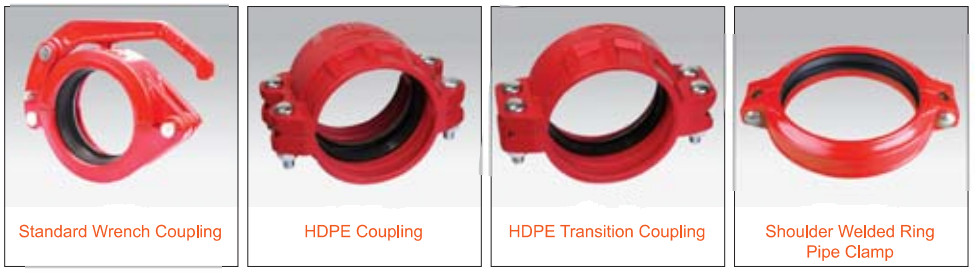

Standard wrench coupling, HDPE coupling, HDPE transition coupling, shoulder welded ring pipe clamp.

1.Faster and safer installation:

Grooved connection system can be mounted up to 10 times faster than conventional connection methods such as welding, threaded connection and soldering.

The dangers of welding are welding arcs, compressed gas, toxic fumes and lack of personal protection against the eyes, hands, feet and body. Grooved connection system eliminates various safety risks, such as welding arcs and fumes. With the grooved connection system, the installer only needs to use a wrench, which is essential for installing a piping system in a confined space.

When welding flange connections, if a product mismatch occurs in the field, only more complicated cutting techniques can be used to re-weld. However, the product of the groove connection system can adjust the system components 360 degrees before fixing, saving huge rework time and correspondingly large cost, greatly improving efficiency.

2.More environmentally friendly, no slag dust pollution:

The groove connection product is more environmentally friendly than welding, brazing, and soldering, because the groove installation process does not require heating, no high temperature, and no welding smog dust pollution.

The grooved joint product is surface treated with electrophoretic paint and is more environmentally friendly.

Flexible couplings are mainly used for grooved pipe connections where adjacent pipe ends allow a certain amount of relative axial displacement, angular displacement and corresponding axial rotation.

Rigid couplings are for grooved pipeline connection. At the joint part, the adjacent pipe ends are not allowed to have relative axial displacement and angular displacement.