GC Series high pressure boiler feed pump

GC series high pressure electric boiler feed water pump is horizontal single-suction multi-stage segmental vertical centrifugal pump, mainly used for boiler feed water, so also known as boiler feed pump. This series of boiler feed water pump is suitable for transport water temperature below 110 ° C or non-corrosive of physical and chemical properties similar to water other liquid, is widely used in industrial and mining enterprises and institutions of the boiler feed water and city life.

-

-

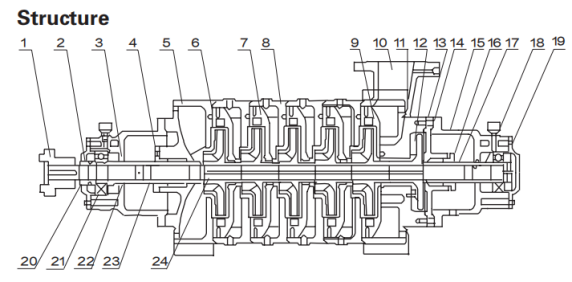

No.

Part Name

Material

No.

Part Name

Material

1

Coupling

HT200

13

Balance Disc

HT200

2

Bearing Cover

HT200

14

Packing Seal

HT200

3

Bearing

HT200

15

Bearing

HT200

4

Seal Cover

HT200

16

Seal Cover

HT200

5

Inflow Section

HT200

17

Seal Sleeve

Q235

6

Impeller

HT200

18

Bearing Sleeve

Q235

7

Guide Vane

HT200

19

Bearing Cover

HT200

8

Middle Section

HT200

20

Bearing Cover

Q235

9

End Guide Vane

HT200

21

Bearing

Bronze

10

Effluent Section

HT200

22

Bearing Sleeve

Q235

11

Balance Section

HT200

23

Bearing Sleeve

Q235

12

Balance Ring

HT200

24

Shaft

45/2Cr13

Type

Flow

( m³/h )

Head

( h/m )

Speed

( r/min )

Shaft Power

( kw )

( NPSH )

r/m

1.5GC-5×2

6

46

2950

3

6.5

1.5GC-5×3

6

69

2950

4

6.5

1.5GC-5×4

6

92

2950

5.5

6.5

1.5GC-5×5

6

115

2950

5.5

6.5

1.5GC-5×6

6

138

2950

7.5

6.5

1.5GC-5×7

6

161

2950

7.5

6.5

1.5GC-5×8

6

184

2950

11

6.5

1.5GC-5×9

6

207

2950

11

6.5

2GC-5×2

10

64

2950

7.5

5.5

2GC-5×3

10

96

2950

11

5.5

2GC-5×4

10

128

2950

15

5.5

2GC-5×5

10

160

2950

18

5.5

2GC-5×6

10

192

2950

18.5

5.5

2GC-5×7

10

224

2950

22

5.5

2GC-5×8

10

256

2950

30

5.5

2GC-5×9

10

288

2950

30

5.5

2.5GC-6×2

15

62

2950

7.5

5.2

20

54

4.9

2.5GC-6×3

15

93

2950

11

5.2

20

81

4.9

2.5GC-6×4

15

124

2950

15

5.2

20

108

4.9

2.5GC-6×5

15

186

2950

18.5

5.2

20

162

4.9

Remark

Parameter table above is only a part of whole. For more, please contact us directly.

-

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and Inspection report will be provided for each shipment

4.Rich operating experience for project orders