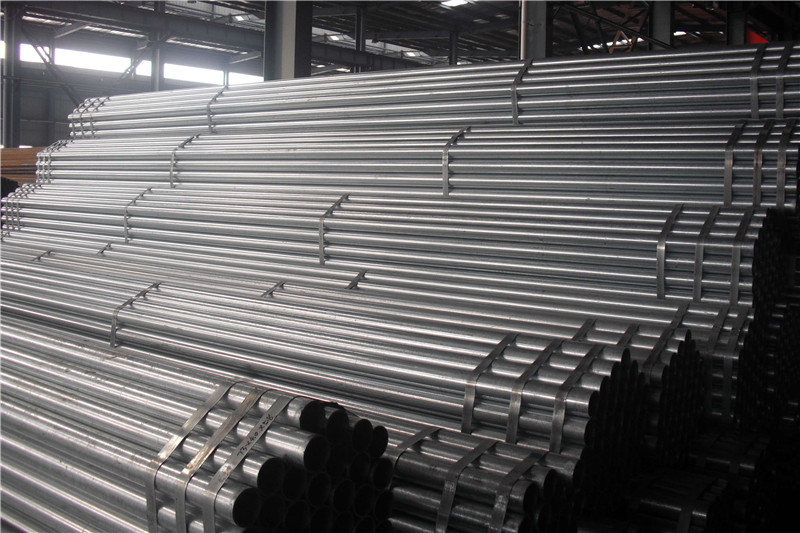

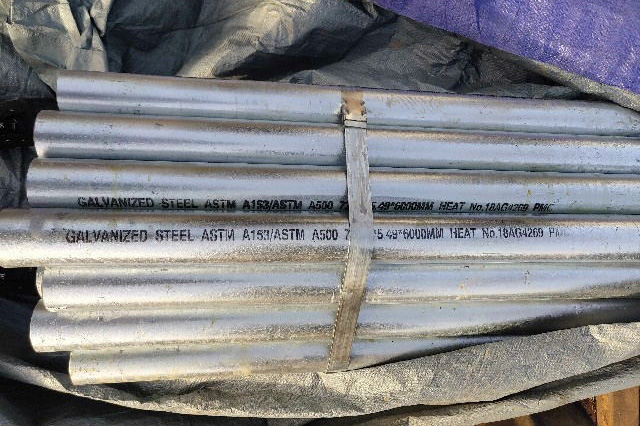

Electric/Hot-dip galvanized steel pipe

Galvanized steel pipe is a carbon steel pipe that is coated with a protective layer of zinc. The zinc layer served as a sacrificial layer, it will get rust before the carbon steel under neath it. Galvanized steel pipe includes Two types: hot-dipped galvanized steel pipe and cold galvanized steel pipe. The galvanized layer will strengthen the anti-corrosion performances of steel pipes.

Hot dip galvanizing is to make molten metal and iron matrix reaction as an alloy layer, so that the substrate and coating two combined. Hot dip galvanizing is to pickle the steel pipe first,in order to remove the iron oxide on the surface of the steel pipe. After pickling, through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform plating, strong adhesion and long service life. The electric galvanized treatment with light & beautiful surface also can be provided.

Hot dip galvanizing process:

Workpiece degreasing→washing→pickling→washing→drying solvent dip fluxing preheated hot dip galvanized→cooling→finishing→rinsing→drying→passivation test

Cold galvanized process:

Chemical degreasing→washing→hot water hot water electrolysis degreasing→washing→ washing→strong corrosive galvanized iron alloy→washing→washing→light→washing→drying passivation

Building and structural material

Mechanical and general engineering purposes

Manufacturing of bus body