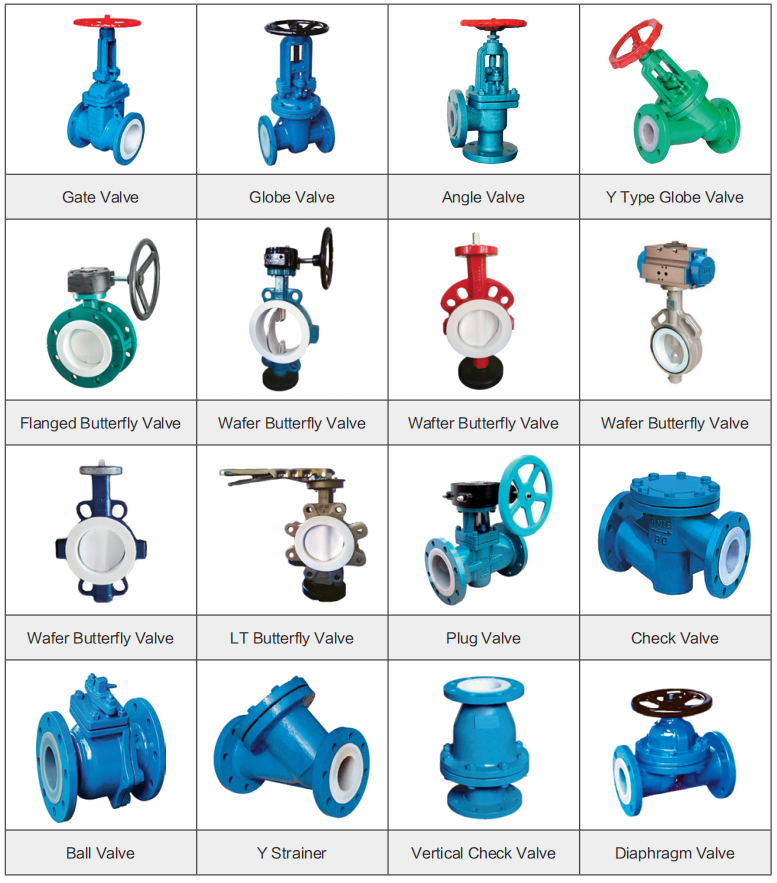

PTFE/PFA/FEP fluorine lined anti-corrosion valve

The fluorine lining valve has the dual functions of switch and flow regulation, which can easily open and close the gas circuit without affecting the flow rate, ensuring the repeatability of the flow. The slow opening reduces the impact of the instantaneous pipeline pressure on the instrument. A damper was added quite to greatly extend the service life of the fluorine-lined valve. Fluorine lining valve is dedicated to controlling corrosive or strongly corrosive media, the surface of the valve body cavity is covered with a variety of fluoroplastics for selection, suitable for different operating temperatures and fluid pipelines, with high strength, good corrosion resistance characteristics

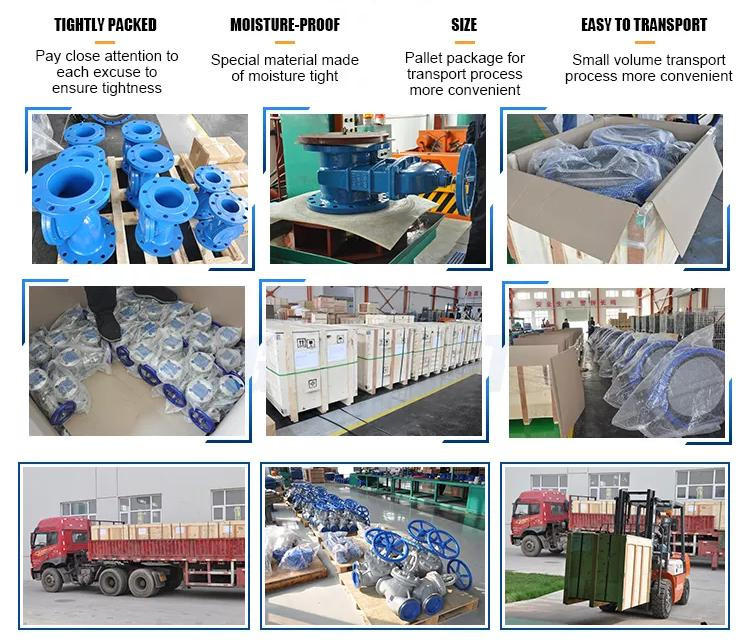

1.OEM is available

2.Full set of valve moulds with different weight to satisfy with customer’s different requirement.

3.Precision casting and sand casting

4.Our own foundry to guarantee fast delivery and quality

5.Epoxy coating with WRAS approved

6.The price of big size valve is very advantageous

7.Certificates available: WRAS/ DWVM/ WARC/ ISO/CE/NSF /KS/TS/BV/SGS/ TUV …

8.Professional QC department to control product quality, and each valve will be arranged hydro test twice before shipment

9.Mill test certificate and inspection report will be provided for each shipment