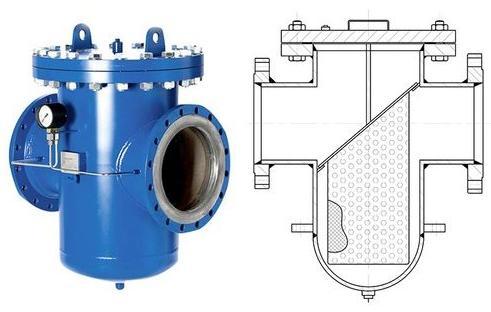

Steel flanged pipeline basket strainer

| Available material |

Standard |

| Body & Cover: EN-JS 1050/A126 Class B/1563 EN-GJS-400 ASTM A 216 Gr WCB ASTM A 351 Gr CF 8/CF 8M ASTM A 351 GR. CF 3/ CF 3M Standard screen: SS 304 / SS 316 SS 304L / SS 316L |

Flange connection:ANSI/DIN/JIS/BS Threaded connection standard:ANSI/ASME B1.20.1 Socket weld:ANSI B 16.11 Butt weld:ANSI B 16.25 |

Basket filter is mainly composed of connecting pipe, cylinder, filter basket, flange, flange cover and fastener. When the liquid enters the filter basket through the cylinder, the solid impurity particles are blocked in the filter basket, and the clean fluid is discharged through the filter basket and the outlet of the filter. When cleaning is needed, loosen the plug at the bottom of the main pipe, drain the fluid, remove the flange cover, lift out the filter element for cleaning, and then install it again after cleaning. Therefore, it is very convenient to use and maintain.

Basket strainers are extremely useful in petrochemical processes,the pharmaceutical industry,the manufacture of paint,power industry, environmental industry, food, and chemical industry, etc.