In general, start the centrifugal pump, according to the specification should be, first pump chamber filled with medium, close the outlet valve, and then open the pump, the purpose is: on the one hand to prevent the start of the current is too large damage to the motor; On the other hand, prevent the instantaneous loss of pressure after starting the pump, resulting in pump cavitation. But many problems cannot be generalized!

For low flow and low head pumps, closing or not closing the outlet valve is not a problem.

For large pumps, the outlet is often opened slightly to prevent the pressure difference between the front and back of the valve after starting, and the outlet valve is not easy to open, so the opening of the outlet valve is slightly opened.

Some centrifugal pumps will slightly open the outlet valve due to preheating and other needs.

If it is with suction, to fully close the outlet valve, and then open the valve ( not self-priming pump ), but also open the pump exhaust valve.

For some special conditions, the outlet valve can not be opened, for example, liquid propylene, if the outlet valve opens first, propylene vaporizes,the pump won't be able to pressure up, so it must be closed first,pump up and then quickly open the outlet valve.

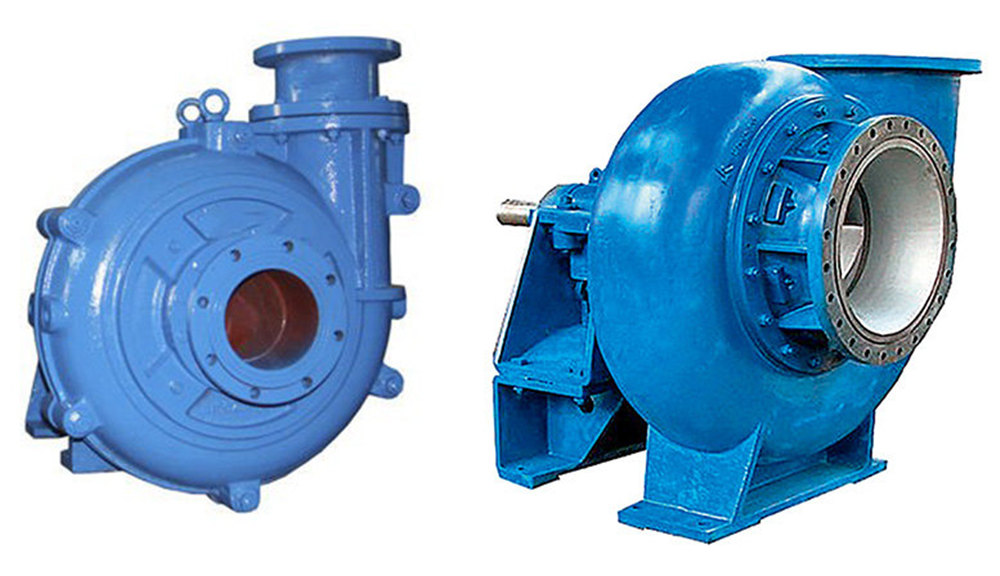

The above are centrifugal pumps. For other types of pumps, the situation is as follows :

1. Large flow start-up characteristics of axial flow pump-fully open valve start-up

The shaft power of the axial flow pump is the largest at the zero flow condition, which is 140 % ~ 200 % of the rated shaft power, and the power is the smallest at the maximum flow condition. Therefore, in order to minimize the starting current, the starting characteristics of the shaft power should be large flow start ( i.e., fully open valve start ).

2. Start-up characteristics of mixed-flow pump-fully open valve start-up

The shaft power of the mixed-flow pump at zero flow condition is between the above two pumps, which is 100 % ~ 130 % of the rated power. Therefore, the starting characteristics of the mixed-flow pump should also be between the above two pumps, and it is better to start with full valve opening.

3. Start-up characteristics of vortex pump-fully open valve start-up

The shaft power of the vortex pump is the largest at zero flow condition, which is 130 % ~ 190 % of the rated shaft power. Therefore, similar to the axial flow pump, the start-up characteristics of the vortex pump should be large flow start-up ( that is, full valve start-up ).

Post time: Feb-20-2023