1.What is stainless steel ?

Stainless steel is a kind of steel. Steel refers to the steel containing less than 2 % carbon ( C ), and more than 2 % is iron. The addition of alloying elements such as chromium ( Cr ), nickel ( Ni ), manganese ( Mn ), silicon ( Si ), titanium ( Ti ), and molybdenum ( Mo ) to the steel during the smelting process improves the performance of the steel so that the steel has corrosion resistance ( i.e., no rust ).

What are 'steel 'and 'iron ', what are their characteristics, and what is the relationship between them ? How do we usually say 304,304L, 316,316L come from ? What are the differences between them ?

Steel : Materials with iron as the main element, carbon content generally below 2 %, and other elements. -GB / T 13304-91 ' Steel Classification '

Iron : a metal element, atomic number 26. The iron material has strong ferromagnetism, good plasticity and thermal conductivity.

Stainless steel : resistant to air, steam, water and other weak corrosive medium or stainless steel. The commonly used steel grades are 304,304L, 316,316L, which are 300 series austenitic stainless steel.

2.Why are there different grades of stainless steel ?

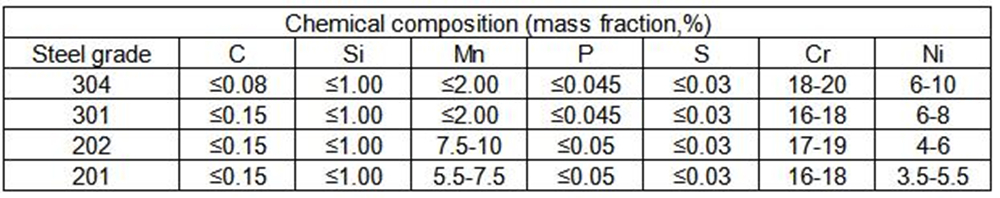

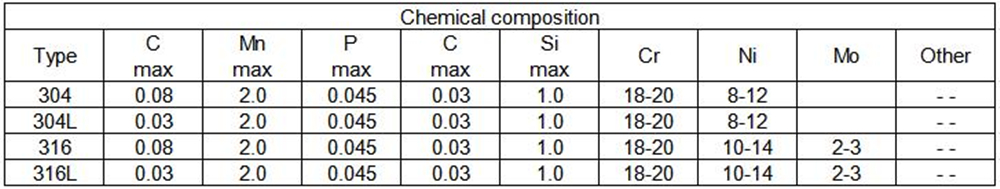

During the smelting process of stainless steel, due to the different varieties of alloy elements added, the amount of different varieties added is different. Its characteristics are also different. In order to distinguish them, different steel grades are crowned. The following is a table of ' alloy elements ' content of different steel grades of common decorative stainless steel for reference only :

304 stainless steel

Performance introduction

304 stainless steel is the most common steel. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Stamping, bending and other thermal processing is good, no heat treatment hardening phenomenon ( no magnetic, the temperature is-196 °C ~ 800 °C ).

Scope of application

Household items ( Category 1 and 2 tableware, cabinets, indoor pipelines, water heaters, boilers, baths )

Automotive accessories ( windshield wipers, mufflers, molded products )

Medical equipment, building materials, chemistry, food industry, agriculture, ship parts

304L stainless steel ( L is low carbon )

Performance introduction

As a low-carbon 304 steel, its corrosion resistance is similar to that of 304 steel under normal conditions, but its grain boundary corrosion resistance is excellent after welding or stress relief. In the absence of heat treatment, it can also maintain good corrosion resistance, and the use temperature is-196 °C ~ 800 °C.

Scope of application

It is applied to open-air machines in the chemical, coal and petroleum industries with high requirements for grain boundary corrosion resistance, heat-resistant parts of building materials and parts with difficulties in heat treatment.

316 stainless steel

Performance introduction

The corrosion resistance, atmospheric corrosion resistance and high temperature strength of 316 stainless steel are particularly good due to the addition of molybdenum, which can be used under harsh conditions. Excellent work hardening ( non-magnetic ).

Scope of application

Seawater equipment, chemical, dye, papermaking, oxalic acid, fertilizer and other production equipment ; photography, food industry, coastal facilities, ropes, CD rods, bolts, nuts.

316L stainless steel ( L is low carbon )

Performance introduction

As a low carbon series of 316 steel, in addition to the same characteristics as 316 steel, it has excellent resistance to grain boundary corrosion.

Scope of application

Products with special requirements for grain boundary corrosion resistance.

Performance comparison

316 and 316L stainless steels are molybdenum-containing stainless steels. Molybdenum content in 316L stainless steel is slightly higher than that in 316 stainless steel. Due to the molybdenum in the steel, the overall performance of the steel is better than that of 310 and 304 stainless steel. Under high temperature conditions, 316 stainless steel has a wide range of uses when the concentration of sulfuric acid is lower than 15 % and higher than 85 %. 316 stainless steel also has good chloride corrosion performance, so it is usually used in the marine environment. With a maximum carbon content of 0.03, 316L stainless steel can be used in applications where post-welding annealing is not possible and where maximum corrosion resistance is required.

Corrosion resistance

The corrosion resistance of 316 stainless steel is better than that of 304 stainless steel, and it has good corrosion resistance in the production process of pulp and paper. And 316 stainless steel is also resistant to marine and corrosive industrial atmospheric erosion.

Generally speaking, 304 stainless steel and 316 stainless steel in terms of chemical corrosion resistance is not very different, but in some specific medium is different.

304 stainless steel was originally developed, which is sensitive to Pitting Corrosion under certain conditions. An additional 2-3 % of molybdenum can reduce this sensitivity, which gave birth to 316. In addition, these additional molybdenum can also reduce the corrosion of certain hot organic acids.

316 stainless steel has almost become the standard material in the food and beverage industry. Due to the shortage of molybdenum in the world and the more nickel content in 316 stainless steel, 316 stainless steel is more expensive than 304 stainless steel.

Pitting corrosion is a phenomenon mainly caused by deposition corrosion on the surface of stainless steel, which is due to lack of oxygen and cannot form a chromium oxide protective layer.

Especially in small valves, the possibility of deposition on the valve plate is very small, so pitting corrosion rarely occurs.

In various types of water medium ( distilled water, drinking water, river water, boiler water, sea water, etc. ), 304 stainless steel and 316 stainless steel corrosion resistance is almost the same, unless the medium chloride ion content is very high, at this time 316 stainless steel is more appropriate.

In most cases, 304 stainless steel and 316 stainless steel corrosion resistance is not much difference, but in some cases may also be very different, need specific analysis. Generally speaking, valve users should have a good idea, because they will choose the material of containers and pipes according to the medium, and it is not recommended to recommend materials to users.

Heat resistance

316 stainless steel has good oxidation resistance in intermittent use below 1600 degrees and continuous use below 1700 degrees. In the range of 800-1575 degrees, it is better not to continuously act on 316 stainless steel, but when 316 stainless steel is continuously used outside this temperature range, the stainless steel has good heat resistance. The carbide precipitation resistance of 316L stainless steel is better than that of 316 stainless steel, which can be used in the above temperature range.

Heat treatment

It is annealed in a temperature range of 1850-2050 degrees, then rapidly annealed and then rapidly cooled. 316 stainless steel cannot be overheated for hardening.

Welding

316 stainless steel has good welding performance. All standard welding methods can be used for welding. According to the purpose of welding, 316Cb, 316L or 309Cb stainless steel filler rods or welding rods can be used for welding. In order to obtain the best corrosion resistance, the welded section of 316 stainless steel requires post-weld annealing treatment. If 316L stainless steel is used, post-weld annealing is not required.

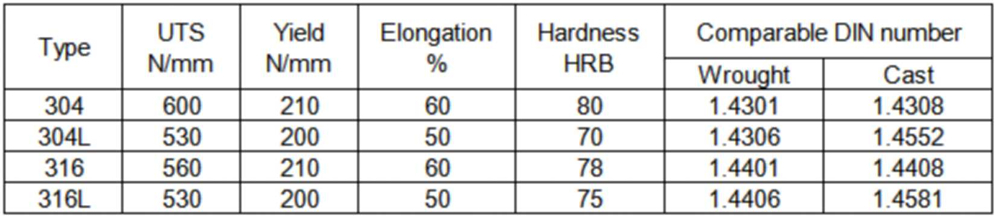

Mechanical properties

Among all steels, the yield point of austenitic stainless steel is the lowest. Therefore, considering the mechanical properties, austenitic stainless steel is not the best material for the valve stem, because to ensure a certain strength, the diameter of the valve stem will increase. The yield point cannot be improved by heat treatment, but it can be improved by cold forming.

Magnetic

Due to the wide application of austenitic stainless steel, it gives people the wrong impression that all stainless steel has no magnetism. For austenitic stainless steel, it can be basically understood as non-magnetic, which is true of quenched forged steel. However, the 304 treated by cold forming will be more or less magnetic. For cast steel, there is no magnetism if it is 100 % austenitic stainless steel.

Low carbon type stainless steel

The corrosion resistance of austenitic stainless steel comes from the chromium oxide protective layer formed on the metal surface. If the material is heated to 450 °C to 900 °C, the structure of the material will change, and chromium carbide will be formed along the edge of the crystal. In this way, a chromium oxide protective layer cannot be formed at the crystal edge, resulting in a decrease in corrosion resistance. This corrosion is called ' intergranular corrosion '.

Therefore, 304L stainless steel and 316L stainless steel have been developed to resist this corrosion. The carbon content of 304L stainless steel and 316L stainless steel is low. Because of the decrease of carbon content, chromium carbide will not be produced, and intergranular corrosion will not be generated.

It should be noted that higher intergranular corrosion sensitivity does not mean that non-low carbon materials are more susceptible to corrosion. In a high chlorine environment, this sensitivity is also higher.

Please note that this phenomenon is due to high temperature ( 450 °C -900 °C ). Usually welding is the direct cause of reaching this temperature. For conventional butterfly valves with soft seats, since we do not weld on the valve plate, it is not very meaningful to use low carbon stainless steel, but most specifications will require 304L stainless steel or 316L stainless steel.

Why is stainless steel rusting?

Why is stainless steel rusty ? When the surface of the stainless steel pipe appears brown rust spots ( points ), people are surprised : ' stainless steel is not rusty, rust is not stainless steel, may be steel problems '. In fact, this is a one-sided wrong view of the lack of understanding of stainless steel. Stainless steel will rust under certain conditions.

Stainless steel has the ability to resist atmospheric oxidation, that is, stainlessness, but also has the ability to corrode in the medium containing acid, alkali and salt, that is, corrosion resistance. However, its corrosion resistance varies with the chemical composition of the steel itself, the state of care, the conditions of use and the type of environmental media. Such as 304 steel pipe, in the dry and clean atmosphere, has absolutely excellent corrosion resistance, but it will be moved to the seaside area, in the sea fog containing a lot of salt, will soon rust ; the 316 steel pipe performs well. Therefore, not any kind of stainless steel, in any environment can be resistant to corrosion, not rust.

Post time: Jul-03-2023